Our sheet metal fabrication guidelines are designed to optimize part manufacturability, enhance the cosmetic appearance, and reduce overall production time. By following these key design considerations, you can achieve high-quality results while maintaining cost efficiency and streamlined production processes.

Maximum Dimensions

| US | Metric | |

| Size | 39 in. x 47 in. | 990.6mm x 1,193.8mm |

| Bend Length | 47 in. | 1,193.8mm |

Minimum Dimensions

| US | Metric | |

| Flat Part | 0.250 in. x 0.250 in. | 6.35mm x 6.35mm |

| Formed Part | 0.500 in. x 0.500 in. | 12.7mm x 12.7mm |

Single Surface

| US | Metric | |

| Bends | +/- 1 degree | +/- 1 degree |

| Offsets | +/- 0.012 in. | +/- 0.304mm |

| Hole Diameters | +/- 0.005 in. | +/- 0.127mm |

| Edge to edge/hole; hole to hole | +/- 0.005 in. | +/- 0.127mm |

| Hardware to edge/hole | +/- 0.010 in. | +/- 0.254mm |

| Hardware to hardware | +/- 0.015 in. | +/- 0.381mm |

| Bend to edge | +/- 0.010 in. | +/- 0.254mm |

| Bend to hole/hardware/bend | +/- 0.015 in. | +/- 0.381mm |

Multiple Surface

| US | Metric | |

| Features separated by two or more bends | +/- 0.030 in. | +/- 0.762mm |

|---|

Tolerances vary on depending on part feature such as bends, offsets, holes, and inserted hardware.

Check out our sheet metal guide for a quick snapshot of our Standard and Cosmetic finishing options available for various sheet metal materials.

Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm).

| Steel | Stainless | Aluminum | Copper | Brass | ||||||

| CRS/HRPO* | Galvanneal | Galvanized | 304-2B | 304-#4 | 316-2B | 5052-H32 | 6061-T6 | C101 | C110 | C260 |

| 0.024 | 0.028 | 0.028 | 0.024 | 0.024 | 0.024 | 0.025 | 0.025 | 0.025 | 0.025 | |

| 0.030 | 0.034 | 0.034 | 0.029 | 0.029 | 0.029 | 0.032 | 0.032 | 0.032 | 0.032 | 0.032 |

| 0.036 | 0.040 | 0.040 | 0.036 | 0.036 | 0.036 | |||||

| 0.042 | 0.040 | 0.040 | 0.040 | 0.040 | 0.040 | |||||

| 0.048 | 0.052 | 0.052 | 0.048 | 0.048 | 0.048 | 0.050 | 0.050 | 0.050 | 0.050 | 0.050 |

| 0.060 | 0.063 | 0.063 | 0.060 | 0.060 | 0.060 | 0.063 | 0.063 | 0.064 | 0.062 | 0.063 |

| 0.075 | 0.079 | 0.079 | 0.075 | 0.075 | 0.075 | 0.080 | 0.080 | 0.080 | 0.080 | 0.080 |

| 0.090 | 0.093 | 0.093 | 0.090 | 0.090 | 0.090 | 0.090 | 0.090 | 0.093 | 0.093 | 0.093 |

| 0.105 | 0.108 | 0.108 | 0.105 | 0.105 | 0.105 | 0.100 | 0.100 | |||

| 0.120 | 0.123 | 0.123 | 0.120 | 0.120 | 0.120 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 |

| 0.135* | 0.138 | 0.138 | 0.135 | 0.134 | 0.135 | |||||

| 0.164* | 0.165 | 0.160 | 0.160 | |||||||

| 0.179* | 0.187 | 0.190 | 0.190 | |||||||

| 0.239* | 0.250 | 0.250 | 0.250 | |||||||

*These thicknesses are available as Hot Rolled, Pickled & Oiled (HRPO) only

Since sheet metal components are produced from a single sheet of metal, the part must have a consistent wall thickness.

Sheet metal thickness varies between 0.024 inches (0.609 mm) and 0.250 inches (6.35 mm).

Looking to transform flat sheets of metal into fully formed, three-dimensional parts? Our functional design aid, the Z Frame, provides comprehensive guidance for creating designs incorporating countersinks and punch-outs to powder coating and silk screening. It delves into fabrication techniques specific to sheet metal while also focusing on design elements that enhance your parts’ structural integrity and aesthetics. It is a practical desktop organizer, adding utility and style to your workspace.

We provide various finishing services to enhance the quality and appearance of your sheet metal parts, including welded assemblies, standard mill finishes, edge breaking, and orbital-sanded surfaces. Additionally, we offer a range of other sheet metal finishing options:

These finishing options ensure that your parts meet both functional and aesthetic requirements.

In-house powder coating is available to streamline production, and parts are powder coated in compliance with government regulations.

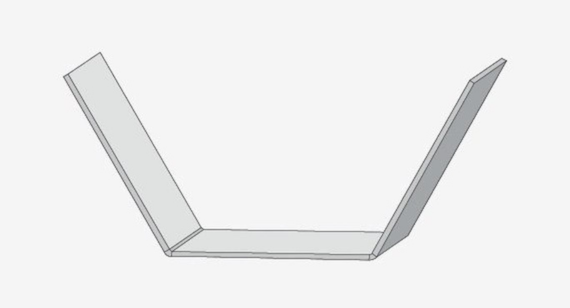

We maintain a +/- 1-degree tolerance on all bend angles to ensure precision in sheet metal parts. While we offer a variety of bend radii, our standard options are as follows:

These four standard bend radii are available with a quick 3-day lead time. Additionally, the minimum flange length for sheet metal parts must be at least four times the material thickness.

We recommend using the same bend radius across all bends for optimal results. Remember that flange length should always meet the minimum requirement of four times the material thickness.

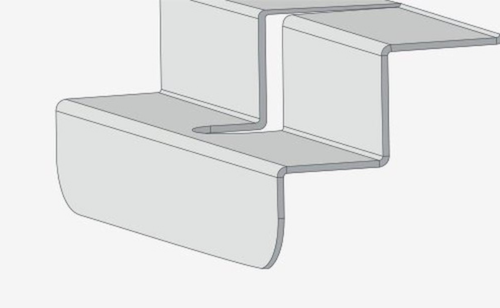

We offer both open and closed hems for sheet metal parts. The tolerance of a hem depends on factors such as the hem’s radius, material thickness, and nearby features.

For optimal results, we recommend that the minimum inside diameter of the hem equals the material thickness, with a hem return length of at least six times the material thickness. This ensures both structural integrity and proper fit during the manufacturing process.

Offsets are commonly used to create Z-shaped profiles in sheet metal parts. We maintain a height tolerance of +/- 0.012 inches (0.304 mm) from the top of the sheet to the top of the form. We recommend an offset of 0.030 inches (0.762 mm) for standard designs.

Additionally, we offer a variety of standard offset options, including:

These options provide flexibility to suit various design needs while maintaining precision in sheet metal fabrication.

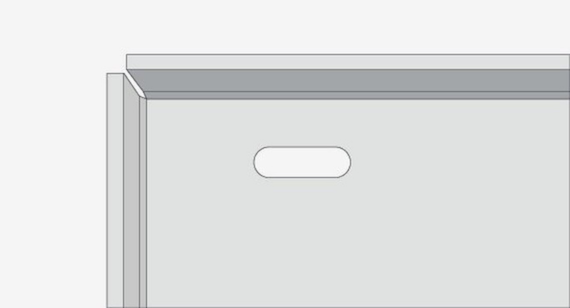

For optimal sheet metal fabrication, holes and slots should have a minimum diameter equal to the material thickness.

The spacing should follow the manufacturer’s specifications when hardware inserts are needed to ensure proper fitting and functionality.

These guidelines ensure that notches and tabs maintain structural integrity while fitting within the design constraints.

We offer both machined and formed countersinks—conical holes that allow screws, nails, or bolts to be inserted flush with the surface of a manufactured object.

For optimal performance, we recommend that the significant diameters of countersinks range between 0.090 inches (2.286 mm) and 0.500 inches (12.7 mm) using one of the following standard angles: 82°, 90°, 100°, and 120°.

The tolerance for formed countersink primary diameter is +/- 0.010 inches (0.254 mm), ensuring precise and consistent results in your designs.

Junying Metal Manufacturing has developed high-level manufacturing technique in production fields of machining.

Address: Gang Kou, Zhong Shan City, Guang Dong Province, China.